This buyers' guide appears in the June 2018 issue of Potato Grower.

It may seem a ways off now, but before you know it, it’ll be time to get those spuds out of the ground. Harvest is the most exciting—and undoubtedly busiest—time of the year for growers. When the time comes, you’ll want to be sure to be prepared with quality, reliable equipment that will take care of fruits of your labors.

Greentronics

(519) 669-4698

(519) 669-4698

www.greentronics.com

RiteTrace

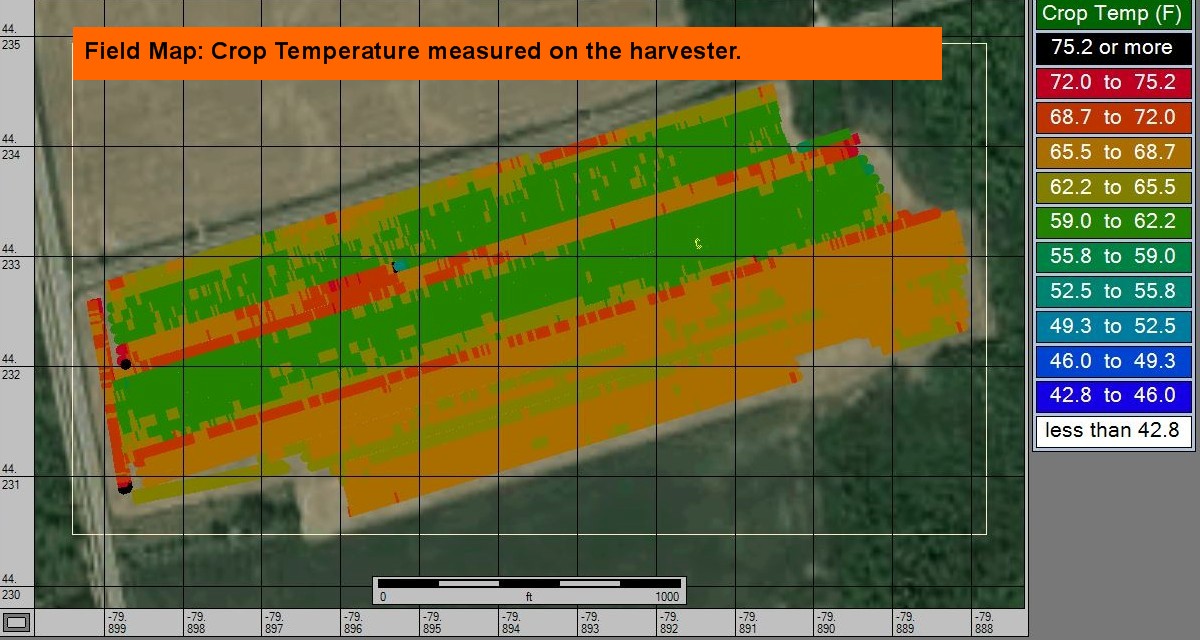

RiteTrace automates record-keeping jobs and precisely logs data for both ambient and crop harvest temperatures, dates and times, and produces 3D maps identifying where each load is located in storages. The system offers a clear and straightforward method for linking stored produce back to field origins, fulfilling many traceability requirements. It also offers agronomic benefits in allowing growers to track quality in storage back to the field. Maps and reports can be reviewed or made available to shippers and buyers. RiteTrace generates numerous reports, allowing users to study efficiencies and traffic flow.

RiteTrace is available in combination with Greentronics’ RiteYield yield monitor. Optional ISOBUS VT compatibility is available for users who prefer to use their in-cab displays to view and access the RiteTrace menus.

Rite Yield

Greentronics’ yield monitor system is easy to implement on potato, carrot, onion, tomato, beet, squash, grape, leafy herbs and a variety of other vegetable harvesters. It is built around one or more load cells, which are installed in a conveyor belt to measure the weight of the crop as it passes on the belt. Growers use yield maps to study and manage variability in their fields and to generate report cards on their progress. Greentronics offers optional integration with John Deere 2630 and with Trimble FMx and TMx displays. These displays map yield in real time and offer wireless data communication.

Kerian Machines, Inc.

(701) 352-0480

www.kerian.com

Kerian Speed Sizer

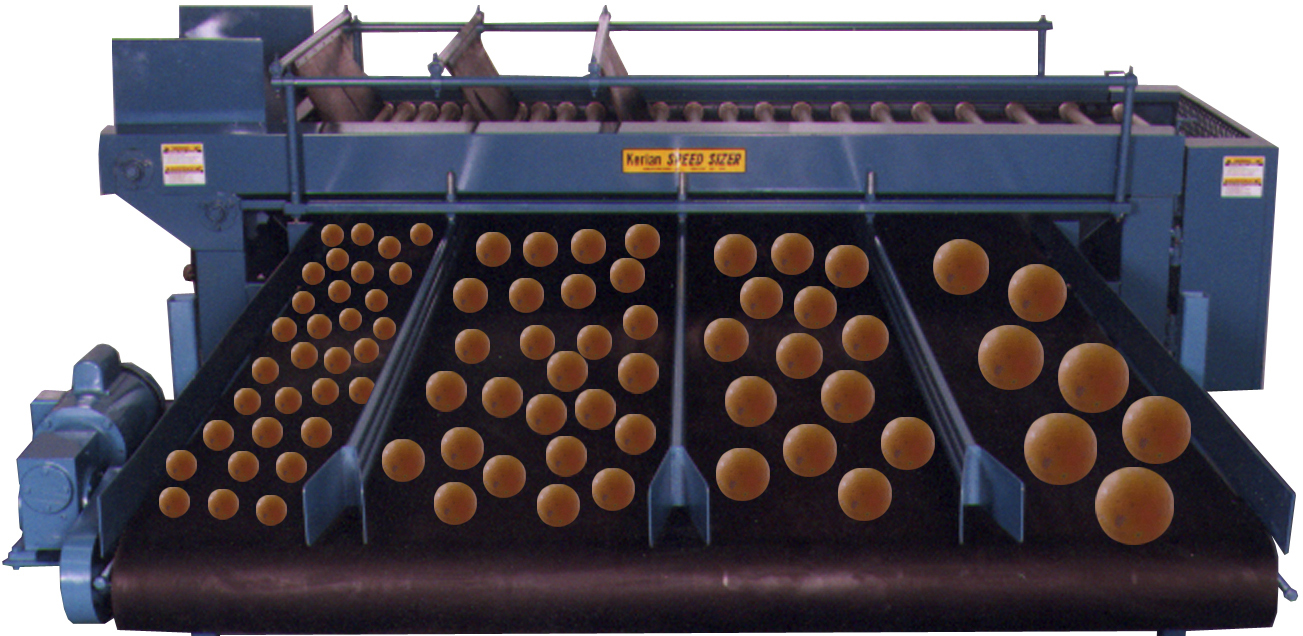

Product description: The Kerian Speed Sizer gently and accurately sorts potatoes by size. It is affordable and proven in use for both round and russet potatoes. With 13 different standard models, the Kerian Speed Sizer can fit any application whether it is a small packing line or a large processing plant. The constantly rotating rollers provide consistent and precise sizing that is fast, gentle, accurate and easily adjustable. All-stainless steel models and stainless steel contact points are also available.

Lockwood Manufacturing

(800) 247-7335

www.lockwoodmfg.com

lkw_contact@crary.com

674EX Harvester

Lockwood’s lineup of harvesters includes seven different models with many modules and options from which to choose to build the machine that works best for an individual operation.

One of those models is the 674EX four-row harvester. Its high-capacity capability is largely due to its 12-foot Extreme Cleaning Table and dual high-efficiency fans. The 674EX harvester is more than equipped to handle high volumes of potatoes while maintaining minimal bruising. Designed and built with the latest Lockwood innovations, it is made of lightweight, strong steel construction and includes larger tires to improve flotation while reducing rolling resistance.

Mayo Mfg.

(208) 520-7049

www.mayomfg.com

Mayo Surge Hopper Unloader

The Mayo Surge Hopper unloader provides gentle unloading and consistent, even flow to the elimination equipment. The 72-inch-wide, live-bottom discharge belt means no dirt buildup and smooth operation. Proximity sensors automatically position the telescoping boom to avoid bruising. Wide, cleated, intake belts make it a great choice for unloading field trucks, quickly and gently and improving any harvest operation.

Orka Food Technology

www.wireless-potato.com.jpg)

www.orkatech.com

Wireles Potato Node

The Wireless Potato Node, manufactured by Orka Food Technology, identifies the exact locations where potato damage takes place. It provides a real-time measure of shock, vibration, rotation, tilting and temperature to which potatoes are subjected, helping to monitor potato conveying, grading and packing installations and transportation from farm location to point of sale.

The Wireless Potato Node identifies exact locations where potatoes are damaged, enabling appropriate corrective action to reduce bruising and losses and improving operational efficiency.

Manufacturers of grading and packing machines use the Wireless Potato Node to ensure that conveyor systems run smoothly and are well-adjusted.

Safe-T-Pull, Inc.

(701) 284-6100

www.safe-t-pull.net

www.strongtruckbox.com

Crop Shuttle

PIC: Crop Shuttle

The Crop Shuttle is the largest, fastest and most versatile crop cart on the market. Customers can choose from 36-, 46- and 56-ton capacities and discharge speeds up to 25 tons per minute. With small modifications, the Crop Shuttle can help harvest potatoes, onions, tomatoes, sugarbeets, cucumbers, pickles, carrots and corn silage, and can be used to load potato planters. Crop Shuttle attachments are being developed to make the Crop Cart capable of spreading lime.

The Crop Shuttle’s patented design has minimal moving parts and changing angles, meaning less buildup of debris while using less hydraulic power; a PTO is not even necessary. The hopper rises into the air while unloading, creating the incline needed without a separate conveyor slowing down discharge and damaging the crop.

Converter Dolly

The Strongbox Converter Dolly has been called by many names: dolly, jo-dog, converter, jeep… By any name it allows the operator to hook a field tractor up to a semi-trailer to load it in the field and return it to the headland without dragging trucks through mud or other unfavorable conditions. This helps reduce compaction and ruts in the field.

Spudnik Equipment Co.

(208) 785-0480

www.spudnik.com

1872 Even Flow

The new 600-hundredweight 1872 Even Flow bin was designed with a 60-inch-wide, high-capacity elevator and a wider, 72-inch bottom belt. This machine is able to handle a higher product flow and is a perfect match for wide, high-capacity eliminators because of its ability to distribute product evenly over the whole width of the elevator. This cuts down the amount of potato layers, helping the eliminator clean and size better. The Even Flow also has an adjustable discharge gate that enables the operator to control the handling effect of the machine. The operator can close the gate to obtain an even discharge flow and break up soft clods; when the gate is opened, the whole pile moves forward, reducing the effects of skinning and bruising. In addition, operation is simplified by all belt speeds being displayed in “feet per minute,” allowing easy and precise adjustment.

Spudnik invites customers to visit their facility and welcomes conversations to better understand grower challenges and discuss their operations.

Tomra Food

(916) 388-3900

www.tomra.com/food

food.us@tomra.com-02B.jpg)

Field Potato Sorter (FPS)

Tomra’s Field Potato Sorter is a sensor-based food sorting machine for unwashed potatoes. It is a robust, high-capacity potato sorter for use in the separation of most foreign material from unwashed potatoes and other root crops.

The FPS has proven itself invaluable in heavy ground conditions, where its unique vision system accurately separates dirt clods, rocks, wood, bone, plastic, glass, metal, rubber and more. Typical labor savings using the FPS can be in the area of 80 percent, with satisfied customers reporting high unloading speeds even in the most challenging conditions.

Tong Engineering Ltd.

+44(0)1790 752771

www.tongengineering.com

tong.usa@tongengineering.com

EasyClean Dirt Eliminator

Tong’s market-leading EasyClean dirt eliminator offers unmatched dirt, vine and root elimination. The EasyClean works exceptionally well in wet or dry conditions while being very gentle on the crop. With inverter direct drive motors on every shaft, Tong’s all electric Blue-Inverter technology ensures energy efficiency and simple machine control.

Tong introduced a new generation of dirt elimination to the vegetable sizing market over a decade ago, revolutionizing dirt elimination in all crop and soil conditions; Tong’s Caretaker is now the top-selling mobile sizer/sorter on the worldwide market. Over the years Tong has gained invaluable knowledge and experience in dirt elimination, allowing the company to offer more effective and proven dirt elimination equipment.

Available as a four- or six-row machine, in standard widths of four, five, six and eight feet, the EasyClean is suitable for use on potatoes, carrots, beets and more. The machine is capable of high-throughput dirt elimination of up to 88 tons of crop per hour.

Advanced Farm Equipment

(877) 287-5711

www.lenco-harvesters.com

Lenco Self-Propelled Harvester

Advanced Farm Equipment (AFE) is the manufacturer of the Lenco self-propelled potato harvesters. AFE strives each year to improve with new technology, innovating hydraulics and electronics for better control and data logging tying into the operator’s GPS, and developing better cleaning devices for removal of debris and foreign materials. AFE also works to make the small things easier, resulting in less down time for the grower.

A double-hinge belt clip extends the life and length of the clip and belt with a tool that permanently replaces stars in the field without disassembling the shaft.