Source: Silicon Republic

Many of the folks connected to Silicon Valley tend to wax lyrically about the internet of things (IoT), possibly because it promises such massive advances in everything from telecommunications, to smart cities and healthcare in between.

One area that has already been benefiting – at least to some extent – is agriculture, where harvesters are already (to a certain extent) semi-autonomous, while in dairy farming the process has become substantially computer-driven.

Given Ireland’s reliance on agriculture as a major source of income, many technological breakthroughs – particularly within IoT – are being made by Irish organisations such as the Tyndall National Institute in Cork.

Yet it isn’t just research groups that are developing next-generation IoT tech. It is also the companies that stand to make considerable amounts of money from machinery that is both incredibly smart, and increasingly robotic.

One such company is farming machinery manufacturer John Deere, known just as much for its machinery as it is for its branded clothing.

A self-propelled sprayer. Image: Deere & Company

Guidance is the name of the game

One person actively working in promoting IoT systems in agricultural hardware for John Deere is Richard Johnson, director of product marketing, who spoke with Siliconrepublic.com at last November’s IoT World Europe conference in Dublin.

He describes modern agriculture as living in a period he refers to as ‘agriculture 4.0’, much like we talk of industry 4.0 and the amalgamation of every technological advancement within the area of IoT.

Right now, he said, much of John Deere’s own focus on IoT remains within the area of guidance as “it is such an economic benefit to customer, also coupled with the fact that, once you invest into that tech, you can quickly get into machine automation.”

For example, there are devices like the AutoTrac Vision camera system, which aligns a crop sprayer with rows of crops to prevent any getting crushed and harming the farmer’s revenues.

Machines working together is next

The next big step, Johnson said, is not just using sensors. “I think the next revolution is connecting machines, connecting fields and connecting operators.”

For example, one or two forager machines on a field operated by humans could be the focal point for an entire fleet of 10 tractors, turning the farmer into a robot foreman.

“That’s the next development in connectivity in machines,” Johnson said.

“But the next one we see in the future – that is there today but where we’re seeing a slower level of adoption – is what we call agronomical optimisation.”

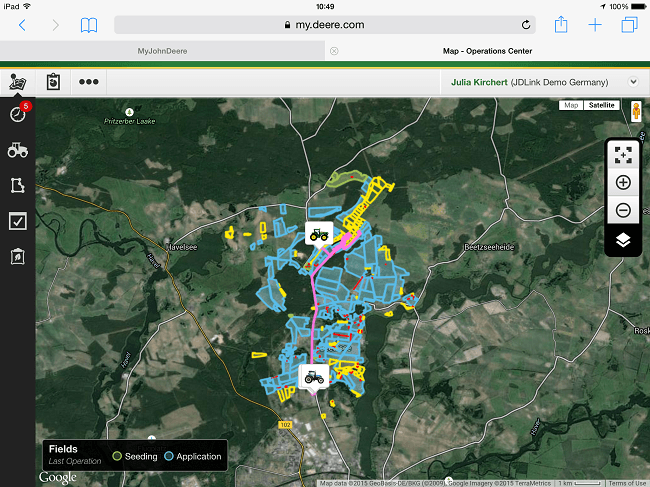

This brings big data into the fray by seeing how customers take all of the data generated from a field and transposing that into a prescription around applications for seeds, fertiliser or sprays for the future.

Sensors working together to show a yield map for a German farm. Image: Deere & Company

Convincing farms of IoT’s benefits is a challenge

The only problem, however, is that Johnson and John Deere believe this is still a development down the line, rather than something in the immediate future.

“I think customers still struggle a bit in deciding how to take that data and put that into a prescriptive and value-add mechanism that really gives payback.”

But this hesitancy is the name of the game, he said, citing the fact that much of the John Deere technology popular today was introduced as far back as 2001, but it took 10 years to finally see a large uptake in it.

He also claims that different agri sectors also show a greater or lesser excitement about new technologies. So while the arable sector might be quick to adopt new IoT tech, the livestock sector might be more hesitant.

Where autonomous makes sense

So, what about sensor-controlled autonomous tractors and vehicles? Are many John Deere customers interested in taking the farmer out of the farm completely?

Not so, Johnson said, as many of the systems in place mean the driver of the tractor has little to do as it is and, in many cases, they aren’t even driving.

Yet there are some places in the world where the scale of some farms is so enormous that designing, building and releasing autonomous agri vehicles makes business sense.

“We’re getting more and more interest in some of the really, really large farming operations in the [former Soviet nations], Russia and South America where they have such huge fields,” he said.

Johnson envisages such enormous operations having between four and six combines with one leader tractor directing the others where to go, but admits that it still poses a challenge for John Deere and farmers in ensuring health and safety standards.

Some farmers are on top of the latest technological developments, however. Recent news suggests that a number of farmers are going so far as to hack John Deere’s systems in a bid to soup up their tractor’s software for greater autonomy.

HarvestLab sensor made by John Deere. Image: Deere & Company

Machine learning for big machines

Understandably, with such data comes great responsibility (and profit, too) as John Deere continues to develop its systems to link with sensors on the ground to provide real-time, preventative maintenance for machines.

“The first stage is maximising our data collection and improving the design of that machine through the data collected,” said Johnson.

Of course, artificial intelligence – that could both predict and alert farmers of such incidents – is seen as the real future in terms of where this collected data can take the company. Last year, it backed the agBOT Challenge in the US to find researchers to develop smart systems to make its vehicles autonomous – an area of particular interest to the company’s director of information solutions, Lane Arthur.

This, Johnson confirmed, is where the company – and agritech as a whole – is heading in the next decade and onwards.