Harvest is the most exciting—and undoubtedly busiest—time of the year for growers. When the time comes, you’ll want to be sure to be prepared with quality, reliable equipment that will take care of fruits of your labors. Never fear; our buyers’ guide is here to help you find the perfect equipment to pull off another successful harvest.

Kerian Machines, Inc.

(701) 352-0480

(701) 352-0480

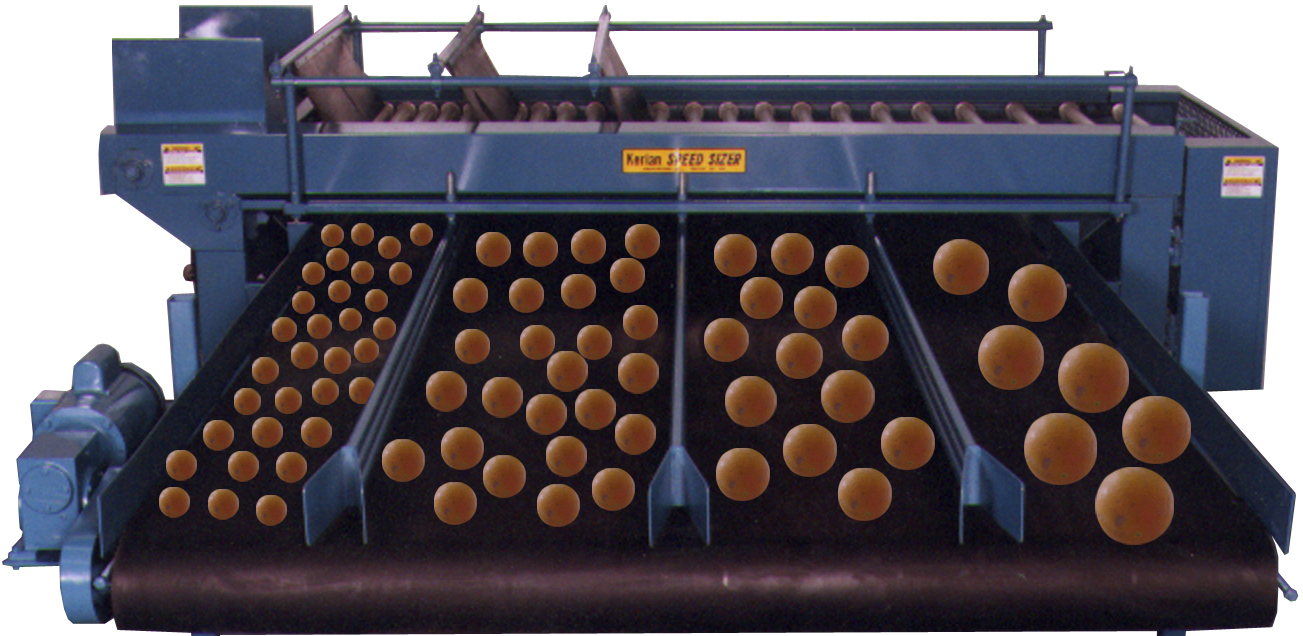

Kerian Sizer

The Kerian Sizer uses a single set of rotating rollers, which gradually separate as they gently carry potatoes forward. The potatoes are thus sized accurately and consistently by diameter. The roller spacing is set by a pair of precisely machined spiral drives with increasing pitch along the length of the sizer. The extreme accuracy of the roller spacing allows precise separation of both long and round potatoes by minimum diameter, with quick adjustment possible by sliding a divider separating sizes. The Kerian Sizer comes in 13 standard models offering each grower a maximum value and a machine perfectly suited to their respective capacities and number of sizes.

Lockwood Mfg.

(800) 247-7335

(800) 247-7335

656DD Windrower

Lockwood’s 656DD six-row windrower includes a double discharge, allowing a grower to dump potatoes in two different rows to improve harvester efficiency. Also available is the patented telescoping rear cross, which allows for either a left- or right-hand discharge. For better depth control, Lockwood has added pressure-sensing support wheels. Last but not least, experience industry leading visibility with a 656DD windrower also includes industry-leading visibility.

Air Harvesters

Air Harvesters

Lockwood has a fantastic solution for growers who grow potatoes in rocky soil conditions. Lockwood’s Air Harvesters are tough on rocks but gentle on potatoes. Using air for separation gently removes potatoes from rocks, minimizing bruising and maximizing cleaning. Many growers have experienced award-winning results year in and year out as Air Harvesters have helped enhance productivity and boost profits.

High-capacity capability allows harvesting of multiple rows, resulting in more acres harvested per day. Dual Crary blowers create optimized air flow, and a 60-inch vacuum chamber effectively lifts potatoes from rocks and other foreign material. Air Harvesters also include a rock box with an auto-dump feature and a can-bus system with user-friendly joystick control.

Safe-T-Pull, Inc.

(701) 284-6100

(701) 284-6100

Crop Shuttle

The Crop Shuttle is the largest, fastest and most versatile crop cart on the market. Choose from 36-, 46- and 56- ton capacity and discharge speeds up to 25 tons per minute. New for 2019 are multiple cleaning bed options that allow operators to remove tare and leave the dirt in the field. The Crop Shuttle is extremely versatile, allowing for use in multiple crops such as sugarbeets, potatoes, carrots, onions, red beets, cucumbers and even corn silage.

The Crop Shuttle is designed so that no PTO is needed to power the hydraulics. Its patented design has minimal moving parts and changing angles, meaning less buildup of debris while using less hydraulic power. The hopper rises into the air while unloading, creating the incline needed without a separate conveyor slowing down discharge and damaging crops.

Spudnik Equipment Co.

(208) 785-0480

(208) 785-0480

Spudnik High-Capacity Storage System

In order to keep harvesting in the field moving forward, the Spudnik high-capacity storage system increases the efficiency of the overall harvesting season. The system includes the new model 1872 Even Flow bin, a 990 or 994 eliminator, 1205 and 1255 conveyors, and an 880 piler. This high-capacity system will increase the storage rate up to 6,000 sacks an hour, allowing the grower to get more done in the critically short time frame of harvest.

Spudnik’s 1872 Even Flow Bin has a capacity of 600 sacks and a 72-inch elevator and bottom belt. A consistent, even flow of product is the key to the success of the entire high-capacity system. The hydraulically controlled back door sets the flow into the Eliminator and can be raised completely out of the way of the product for increased flow or to accommodate varieties with sensitive skin. The 42-inch Conveyor line moves the large volume of potatoes gently and smoothly through the storage to the 48-inch piler.

Tomra Food

+32 16 396 396

+32 16 396 396

Tomra 5A Sorter

The Tomra 5A sorting machine brings to the table more than 98 percent removal rate of foreign objects, quality inspection and peel quality control. Running the highest capacities in the industry, this process potato sorter significantly increases the level of food safety and yield.

The Tomra 5A uses top and bottom sensor banks to view each individual object in flight using a combination of pulsed LED, camera and near-infrared to perform targeted spectroscopy with 1-millimeter precision. The proven and dependable technology guarantees a superior defect detection and quality control. The sorter can be complemented by the peel control module measuring the peel quality and calculating the peeler’s optimal steam time. This combination delivers a better and more stable detection of defects and peel quality. Real-time adjustments to the sorter’s and peeler’s settings result in faster, more accurate reactions to changes, improving the yield and quality of the final product.

Tong USA

(231) 924-5647

(231) 924-5647

(833) 844-8664

Tong Barrel Washer

Built with efficiency, reliability and ease of maintenance in mind, Tong’s proven barrel washer has been enhanced with a number of new and advanced features. A new direct-drive, inverter-controlled barrel drive shaft with heavy-duty coupling replaces the traditional chain-and-sprocket drive system, enhancing simplicity, and longevity of the barrel washer’s drive system. An all-new washer door now brings users even greater control of crop flow, with a unique split-door design that is easily and fully adjustable via electric actuators.

The next-generation barrel washer also features a new, thicker stainless steel barrel drum, which is fitted as standard to all models, and is uniquely perforated for the gentlest handling of crops. A simplified top-shaft design incorporating Cooper split bearings is now available as an option to eliminate the need for shaft removal when changing bearings, making maintenance even easier. Other new features include a heavy-duty direct-driven auger, a newly designed floating debris remover, and a centralized greasing point.

Manufactured in barrel lengths from 4 to 16 feet, and widths from 24 to 60 inches, Tong barrel washers can be specified as a stand-alone unit or integrated into a new or existing handling line.