This buyers' guide appears in the August 2018 issue of Potato Grower.

Ag-Pak, Inc.

(716) 772-2651

www.agpak.com

info@agpak.com

AP7000CW Double-Head Wicketed Bagger

The Ag-Pak AP7000CW is a double-head wicketed bagger with integrated check weighers. This fast machine can bag and weigh 5-pound portions of potatoes at rates of up to 50 bags per minute. Standard bag sizes are 2 to 20 pounds. Other bag sizes may be run with modifications.

Two individual collectors feed dual bagging heads. Each side of the AP7000CW can be run separately, making bag changes easy with no downtime. A separate check weigher sits directly behind each bagging head. The check weighers immediately check portion weights. Filled bags are fed to a rear cross conveyor which can send bags to either side. Rejected bags are deflected from the conveyor. Kwik-Lok closers are standard. Multiple printing options are available.

Reliable and rugged, the AP7000CW is has a robust design featuring stainless collectors, heavy-duty components, a UL-listed electrical cabinet, and a small footprint. The AP7000CW is supported by Ag-Pak’s experienced service technicians and parts specialists.

Idaho Package Co./Kapstone Container

Idaho Falls: (208) 529-0891

Fruitland: (208) 453-9930

www.idahopackage.com

www.kapstonepaper.com

Improved Capabilities & Service

Idaho Package Co. and Kapstone Container continue their partnership to serve the Idaho potato industry with improved c apabilities, quality, locations and service.

apabilities, quality, locations and service.

Kapstone Container in Twin Falls, Idaho, recently went through a major capital spend to improve quality and efficiency. A new BHS 110-inch corrugator is currently being installed and will provide the highest-quality corrugated board available. Kapstone also installed a high-speed Bobst 8.20 four-color, high-speed Flexo—a machine that prints, slots, scores and glues corrugated boxes—to go with its many other abilities. Kapstone’s new corrugator and Flexo will provide the industry with the finest boxes on the market.

Idaho Package recently completed construction of a new location in Fruitland, Idaho. This new, 68,000-square-foot facility will help the company service all of southern Idaho. IPAK now has locations in Idaho Falls, Caldwell and Fruitland. All locations are food grade safe, third party-audited and staffed with long-term professionals to help design, manufacture, store and deliver the best packaging products.

Wyma Solutions

+64 21 403 919

www.wymasolutions.com

Mud Separator

Wyma’s Mud Separator extracts mud from wash water so solids can be transported away and water can be reused. Wash water enters the mud extraction system, where a patented plate pack separates mud and water. Water exits through an outlet near the top. An auger can be fitted inside the cone to help thick, compressed mud exit at the bottom. Mud can then be transported away. A vibrator helps the solids move to the outfeed; a knife valve controls discharge.

This system uses no polymers, flocculants or coagulants. It has few moving parts and is low-maintenance. For best results, this equipment can be used with a Wyma rotary screen filter to remove large debris before wash water enters the mud separation system.

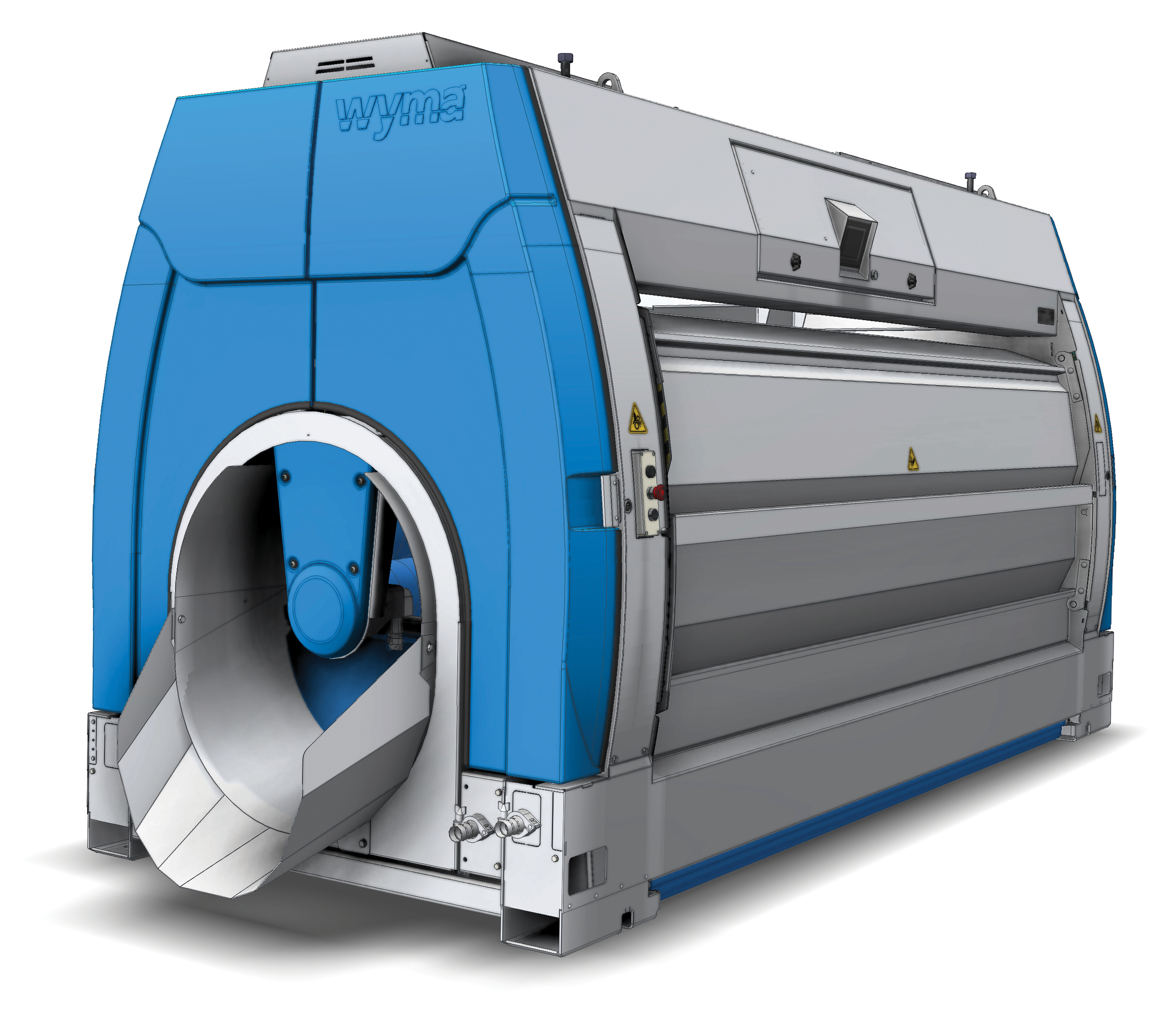

V4 Vege-Polisher

Wyma’s V4 Vege-Polisher improves the appearance of fresh vegetables, resulting in more premium-packed produce and an increased presence on retailers’ shelve s. Wyma’s experience with rotary brush drum technology and brush specification means vegetables are washed and polished to the highest retail standards.

s. Wyma’s experience with rotary brush drum technology and brush specification means vegetables are washed and polished to the highest retail standards.

The V4 has a rotating drum made up of rows of nylon brushes. Produce enters via a large infeed chute. Two water pipes spray fresh and/or recycled water on the produce as it travels through the drum. Produce is washed and polished as it rubs against the rotating brushes and against other produce. At the outfeed, produce slides down a chute with minimal drop for a smooth transition to downstream equipment.

Rietveld Equipment

(815) 936-9800

www.rietveldequipmen t.com

t.com

Potato Cleaning Lines

Rietveld Equipment is the U.S. distributor for Allround Vegetable Processing, Meconaf Dust Extraction and Protec Optical Sorting. Being a fourth-generation grower/packer/shipper gives Rietveld the experience and the understanding of the equipment needs for today’s grower/packer.

Allround is known for its quality machinery and competitive pricing. They provide complete washing, grading and cleaning machinery with free two- and three-dimensional drawings of your complete line, or individual machines in your existing line. They build complete lines with capacities from 1 to 100 tons per hour.

Meconaf has over 20 years’ experience installing custom dust collection systems in the seed potato industry in Europe.

Protec has over 3,500 installations worldwide for optical sorting in the food industry. Their machines have either two- or three-way separation.

With a goal of achieving proven worldwide innovation, Rietveld is sourcing new companies to the U.S. market that have proven themselves in over 80 countries worldwide. These companies look for new ways to mechanize and provide savings on labor. Rietveld Equipment offers full installation and service for all the equipment it distributes to the U.S. market. Rietveld specializes in equipment for handling, grading, sorting and cleaning, from the truck to the final package.

Paxiom Group

(833) 4-PAXIOM

www.paxiom.com

info@paxiom.com

Compact Modular Pick-and-Place Cell

Paxiom Group’s new compact robotic pick-and-place cell can be combined with synchronized conveying systems and incorporated into virtually any existing end-of-line packing process.

The top-load modular cell is equipped to pick and place various finished package types including bags, wrapped products, rigid containers, cartons and widgets into both cases and trays. The packing unit is engineered to operate using either vacuum or mechanical pick-up. Using servo drives, the modular cell assures gentle and precise product handling while maintaining product integrity. With the ability to properly orient logos and pack multiple layers of product into the erected case or tray, the modular cell is as flexible as it is dependable.