(317) 787-9421

www.american-newlong.com

Robotic Palletizer: American-Newlong's EC-201 Robotic Palletizer has a payload capacity of 440 lbs. and a palletizing capacity of 1,600 cycles per hour. The EC-201 palletizes bags, cases, pails and other various products. It also has four axes for maximum flexibility.

Robotic Palletizer: American-Newlong's EC-201 Robotic Palletizer has a payload capacity of 440 lbs. and a palletizing capacity of 1,600 cycles per hour. The EC-201 palletizes bags, cases, pails and other various products. It also has four axes for maximum flexibility.

The weight of the mechanically balanced arm can be supported by a single finger. This unique design allows the EC-201 to use less energy and reduce stress on the arm joints, bearings, pivot points and floor supports. A standard touch-screen allows personnel to change palletizing programs in under five seconds, utilize onboard warning systems, review error occurrences and take corrective measures, monitor I/O in real time, track inventory by specific programs, compare running and powered-up hours and monitor the machine in real time.

American-Newlong, Inc. is the world's leading manufacturer of automated, open-mouth bag packaging and closing systems and equipment. American-Newlong equipment is proven to perform reliably in the food, fertilizer, grain, feed, powder and chemical industries, among others.

(305) 622-4070

www.eaglepm.com

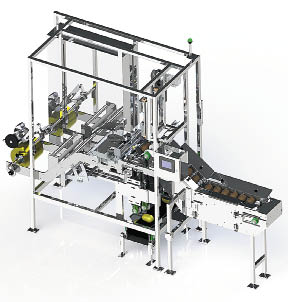

Boxxer T-18 Case Erector: The new Boxxer T-18 automatic case erector and bottom tape sealer is the most affordable and compact erector available on the market today. The Boxxer T-18 can run both regular-slotted and half-slotted style boxes and will erect and tape up to 18 boxes per minute.

Boxxer T-18 Case Erector: The new Boxxer T-18 automatic case erector and bottom tape sealer is the most affordable and compact erector available on the market today. The Boxxer T-18 can run both regular-slotted and half-slotted style boxes and will erect and tape up to 18 boxes per minute.

As a single operator machine, the Boxxer T-18 is mobile and easy to move. Capable of producing a wide range of boxes, size changeover is quick with no part changes required. The unit offers a broad range of features, including an Omron PLC, color touch screen, high-capacity blank hopper and easy access panels with safety switches. The unit is solidly built with a welded steel frame construction, includes casters for easy mobility and is available for left- or right-hand operation.

The Boxxer T-18 transfers a blank from the supply hopper to the erecting station where the blank is opened, the minor flaps are folded and then the major flaps. The erected case is moved through the tape cartridge where a two- or three-inch tape is applied and the case is now ready to be filled.

(877) 688-7369

www.emeraldautomation.com

AF-40 Potato Wrapper: The AF-40 Potato Wrapper uses our unique, patented belt design to wrap potatoes in aluminum foil at a rate of 40 per minute. This one-of-a-kind machine uses rolls of foil rather than individual sheets. Product is brought in via a servo-operated roller in-feed and softly dropped into catch gates. A photo electric eye triggers the servo-driven plunger to gently drive the product through the pre-cut foil and into the wrapping belts. The wrapped product is deposited onto the discharge conveyor.

AF-40 Potato Wrapper: The AF-40 Potato Wrapper uses our unique, patented belt design to wrap potatoes in aluminum foil at a rate of 40 per minute. This one-of-a-kind machine uses rolls of foil rather than individual sheets. Product is brought in via a servo-operated roller in-feed and softly dropped into catch gates. A photo electric eye triggers the servo-driven plunger to gently drive the product through the pre-cut foil and into the wrapping belts. The wrapped product is deposited onto the discharge conveyor.

The AF-40 is capable of wrapping 70-, 80- and 90-count potatoes and features Allen Bradley controls, easy-to-use Operator Interface with on-board help screens, and servo-driven film feed. The Servo Knife Assembly option provides for a completely airless design. The machine is manufactured with a heavy-duty frame, comes with a powder coat finish and also has the option of stainless and wash-down packages. Emerald Automation's Panel Shop provides the U.L. 508 listed enclosure and the easy access lexan guarding provides convenience for machine maintenance and troubleshooting.

(209) 334-1999

info@agrayvision.com

AgRay Vision is built on over 25 years of experience in the potato-sorting industry. Its new system takes proven modules-singulation, x-ray, slide ejection, computing-and integrates them into a seamless system for accurately sizing, sorting, detecting internal and external defects and shape grading of potatoes.

AgRay Vision uses complex proprietary morphological detectors to identify internal defects. The system can also detect misshapen potatoes (heart, banana, bottle, barbell and other shapes). In addition, the system can identify knobs, depressions, growth cracks, digger cuts and excessive dirt.

The AgRay software has the ability to process two potatoes individually even when they are touching, thus reducing recycling and increasing overall throughput.

(321) 508-3392

www.guardianmfg.com

Antimicrobial Ozone Wash: Guardian Manufacturing, Inc. offers ozone-based antimicrobial wash/rinse systems for use on tuber wash and packing lines. The Ensure-ATS (antimicrobial treatment system) provides tubers a final wash or rinse step for any surface borne pathogens prior to packaging or storage. Treatment of the surfaces inhibits cross contamination and assists in extending shelf life.

Guardian has successfully built and delivered hundreds of ozone gas treatment and wash systems specific to the potato industry. The systems can accommodate any size facility and can be configured for basic, no frills operation or with ORP, DOM (dissolved ozone monitor) or gaseous ozone sensors (pile storage) for system control. Systems can also be remotely monitored and controlled through local intranet or Internet connections.

(800) 219-2245

www.chinookequipment.com

Procheck System: The Procheck System carton check-weigher from Chinook Equipment will automatically check cartons in motion as they pass over the check scale. Rejects are automatically diverted to a parallel reweigh station where an operator can adjust the weight of the carton on a separate static scale.

After necessary adjustments in weight are made, the carton is returned by the operator to again go over the automatic check-weigher and on to the carton closer. This system also includes automatic traffic control so that only one carton at a time is on the check-weigher. The operator can be freed up to do other work, as this system can be set up to allow 10 or more cartons to be held in the re-weigh area.

(716) 772-2651

www.agpak.com

NEWTEC 4014XB Weigher: For over 45 years, Ag-Pak has supplied industry-leading produce packaging equipment. They offer weighing, bagging, optical sorting, washing and polishing equipment from the world's best manufacturers, featuring NEWTEC and Haith.

The Ag-Pak NEWTEC 4014XB weigher is a scale that will provide a new industry benchmark in speed and efficiency, while delivering the accuracy and user-friendliness for which NEWTEC has always been known. The 4014XB is a 14-head scale, designed for large product, and can be configured with two Ag-Pak AP6000 double-wicketed poly baggers, two C-Pack 929 clippers or VFFS machines. With weighing speeds of up to 80 portions per minute, this equipment will set benchmarks for the lowest equipment price-per-bag per minute and the highest productivity per square foot of floor space. The 4014XB is constructed in stainless steel and has an easy-to-use touch-screen display.

www.nnz.nl/us/introduction

From a stand-up, bottom-gusseted film bag to a pillow pack, it seems that one of the main ingredients is a large area for high-quality printing that can be used for recipes or a picture of the finished product.

"The USPB has determined through marketing studies that eye-catching print, such as a finished steaming baked potato with melted butter and toppings is what appeals to the shopper. While being able to see the quality of the potatoes is important, they also want to see what they can do with the potato once they get it home," says Steve Greenfield, Director of Sales & Marketing.

The use of a vertical form fill-and-seal machine accomplishes this because one machine can offer so many different styles of bags. In addition, just by changing the type of film used, a packer can accommodate their customer's needs, whether it be a microwaveable stand-up pouch using laser or micro-perforated polypropylene film, or a polyethylene pillow pack with high graphics.

(302) 653-2000

www.thomasmoore.com

Thomas E. Moore, Inc., based in Dover, Del., is a produce packaging equipment manufacturer and distributor. They specialize in equipment designed to convey, wash, size and package all types of produce, with a concentration on potatoes.

They are an exclusive distributor for Verbruggen palletizing equipment, which is based out of The Netherlands. Verbruggen palletizers are showing up in many progressive packing sheds in the United States. Automatic palletizing is becoming a necessity for many packers because of the many advantages it allows. Verbruggen palletizing equipment offers the packer an economical, low-maintenance method of stacking all sizes of potato bags, boxes and RPC's. These palletizers are offered in several different models, and are available in semi-automatic or fully automatic systems.

(715) 627-4826

www.volmcompanies.com

Ultratech Mesh: A third-generation, family-owned American business, Volm Companies, Inc. has served produce packagers for more than 60 years. It is a company that sets trends and breaks new ground in both packaging technology and customer service.

Volm offers a complete line of packaging options. One of the latest innovations is Ultratech Mesh, a lightweight and strong material delivering performance, breathability and stability while using less material and consuming less fuel in production and transportation.

Volm also sells and supports packaging equipment and systems. Being a forerunner in this field has contributed to a natural market leadership in consultancy services, delivered by the Volm Equipment Team (VET) of productivity experts.

(800) 279-2689

www.tristeelmfg.com

Felt Drying Table: The TriSteel Felt Dryer provides excellent drying capabilities while exceeding certain aspects of Sponge Drying Tables. Felt rollers are less likely to be damaged and replacement time is greatly reduced versus sponge donuts. Water absorbent felt sheets are wrapped around stainless steel rollers for a complete drying roller. A lower rack of stainless-steel squeeze rollers tensioned by springs and manually adjusting the height of the squeeze rack put constant pressure to the drying rollers. A plastic wiper is also employed to wipe excess water off the squeeze rollers. The machine is designed and built with a heavy framework, premium motors and gear reducers, hardened sprockets and roller chain drive.

(607) 566-2234

www.hainesequipment.com

Dual Bulk Sack Filler: The Haines Dual Bulk Sack Filler features a dual bag design that allows continuous operation of the unit. It has hydraulic operation of the lift units, a hydraulic bag release and high-capacity belted rear elevator.

(208) 677-7724

www.boiseinc.com

Corrugated Containers: Boise Inc. maintains a razor-sharp focus on producing high-quality corrugated containers that do exactly that-protect precious cargo.

With five corrugated container plants in the Northwest, a corrugated sheet feeder in Waco, Texas, and a corrugated sheet plant in Sparks, Nev., Boise, Inc is poised to handle all potato packaging needs.

(208) 529-0891

www.idahopackage.com

Black and White Light Diffusing Film: This is also a laminated film that diffuses harmful light rays that cause greening in potatoes. The film is used in a Fox Combo bag that is partially mesh and partially film. The bag comes fully wicketed so it can be run on automated bagging equipment. The retailer displays the product film side up and gets the benefit from point-of-sale graphics printed on the bag and the light diffusion and protection from greening that allows for longer shelf life of the potatoes. The outer layer of the lamination is white, which further enhances the graphics. The mesh side allows for transmission of moisture and atmosphere so the product breathes properly to also extend shelf life. The package is fully recyclable after use. There are several large retail chains currently using or moving to this product to help reduce shrink at the store level.

(661) 831-7553

Expanding Roll-Sizer: The Ernst Expanding adjustable Roll-Sizer is designed to speedily size produce by means of precision-controlled rollers. Spacing of rollers is regulated by control handles conveniently placed on the sides of the sizer. Smallest sizes are removed first, then each larger size is removed progressively as the produce flows through the sizer. Produce is carried away by conveyor belts passing through the sizer. Most Ernst sizers have over 200 bearings, to prevent wear. It is not uncommon to find Ernst Sizers working in the field for over 30 years. The Ernst sizer achieves its accuracy by having the same size opening between its rollers throughout the one drop-out size.

(877) 311-3422

www.midwesternbag.com

Ventilated Bulk Bags: As one of the leaders in distributing polypropylene and packaging supplies, Midwestern Bag & Supply provides a wide range of packaging solutions for the potato industry. Ventilated Bulk Bags have been Midwestern Bag & Supply's premier product.

Midwestern Bag & Supply also offers reconditioned Ventilated Bulk Bags (F.I.B.C.), small polyethylene, mesh and paper bags. Midwestern Bag & Supply can also provide custom bags upon request.

Midwestern Bag & Supply is able to stand apart from the competition by offering customers additional options when it comes to their bulk packaging needs. By utilizing our global distribution network, Midwestern Bag & Supply is able to exceed expectations by accommodating custom orders and delivering exceptional prices without sacrificing quality. Each bag order is strength-tested to ensure quality and safety.

Located in the Midwest, Midwestern Bag & Supply is the ideal shipping point to growers across the nation.