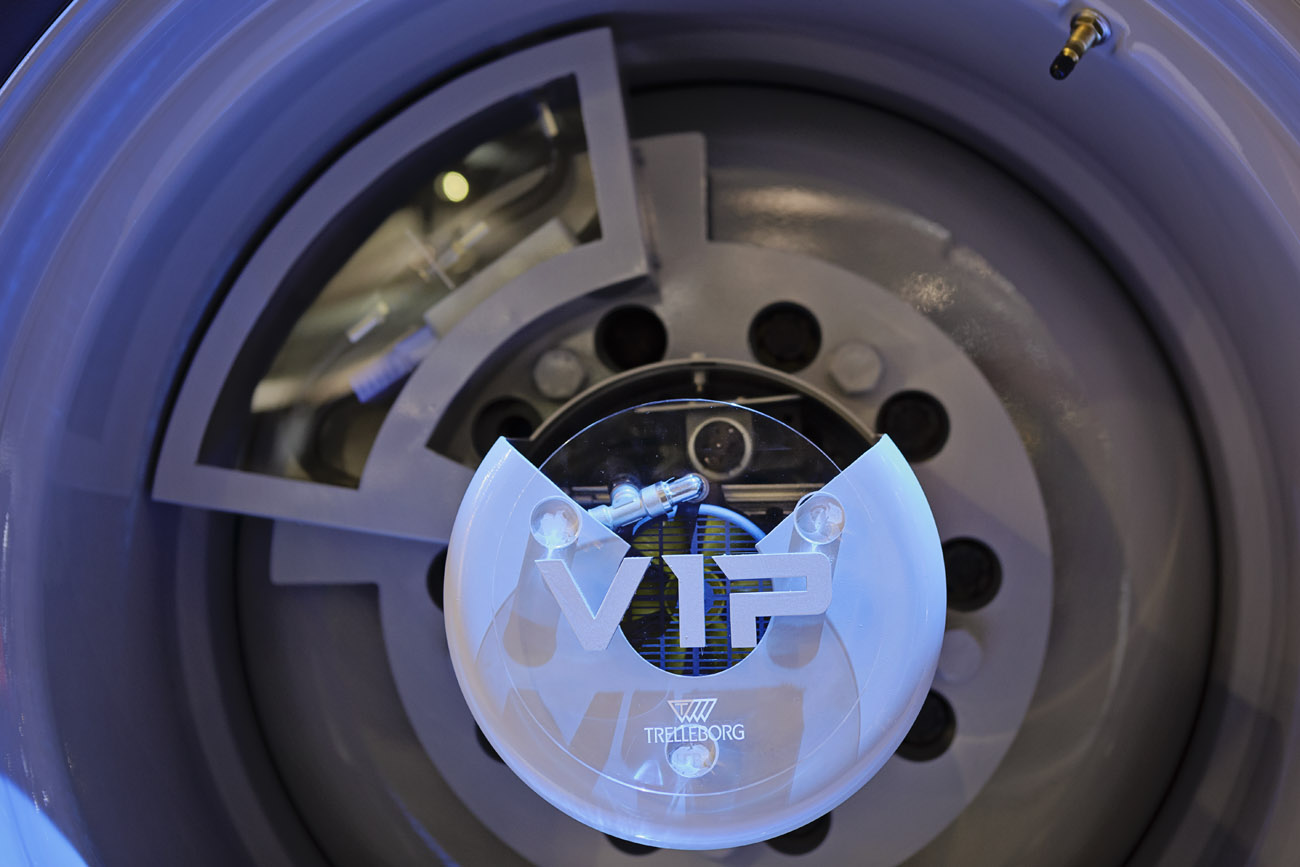

Trelleborg intoduces its latest innovation, the Variable Inflation Pressure (VIP) system. The VIP system is a smart and autonomous complete wheel capable of self-adjusting the pressure of a harvester’s tire during operation according to its precise load, optimizing the tire’s footprint in order to reduce soil compaction.

“The Trelleborg VIP system represents a major step forward and a great new advancement that producers will benefit from in North America,” says Andrea Masella, brand manager for Trelleborg’s agricultural and forestry tires in North America. “The VIP system is not only able to measure and/or change the tire pressure but also, being an intelligent system, of determining and adopting the right pressure at the right time and in the right place, without manual intervention. This is completely in line with the precision farming philosophy. Self-adjusting tires to their optimal pressure during harvest, the VIP system saves the time required for pressure calculations and for inflating and deflating tires. Inflation and deflation takes place on the move, avoiding downtime.”

Tests show that the VIP system achieves better flotation, lowering soil compaction by as much as 10.5 percent and increasing crop yield up to 5 percent compared to a standard wheel. This is due to the fact that in a standard wheel, the pressure within the tire is constant, so the footprint of the tire varies according to the load, limiting the effectiveness of the tire. As the Trelleborg VIP system changes tire pressure depending on the load, the footprint of the tire remains constant at its maximum dimension.

Tests show that the VIP system achieves better flotation, lowering soil compaction by as much as 10.5 percent and increasing crop yield up to 5 percent compared to a standard wheel. This is due to the fact that in a standard wheel, the pressure within the tire is constant, so the footprint of the tire varies according to the load, limiting the effectiveness of the tire. As the Trelleborg VIP system changes tire pressure depending on the load, the footprint of the tire remains constant at its maximum dimension.

Directly integrated on the tire’s rim, the VIP system consists of a set of sensors measuring several parameters including load, pressure and temperature, along with an electronic central processor controlling a compressor and a valve to adjust the pressure. The VIP system automatically senses whether the machine is in the field or on the road and modifies pressure accordingly, inflating on the road or deflating in the field.

The system also detects when, on the same axle, the load on the right tire is different from the load on the left tire. This provides an advantage on slopes, where the VIP system can set two different pressures according to data received. Maximum safety is thereby ensured, along with high flotation, a constant footprint, excellent handling and low soil compaction. All of this contributes to better efficiency and productivity for the farmer.

Not only giving benefits during harvest, the VIP system also reduces fuel consumption and emissions in post-harvest plowing operations. This is due to the fact that a soil with low compaction allows the plow to advance more easily, reducing working time and operating costs.

Already recognized as a significant innovation, the VIP system received a gold medal at the 2017 SIMA Innovation Awards. A prestigious accolade within the agricultural industry, the award acknowledges Trelleborg’s longstanding commitment to developing innovative solutions that boost productivity and efficiency while enhancing agronomic results, reducing operating costs and overall environmental impact.

Contact Trelleborg at www.trelleborg.com/en-us/wheels.