Johnny Fraser considers water management one of the keys to profitably growing crops on his diversified New Zealand farm. Thanks to Precision VRI, a new precision irrigation product from Lindsay, Fraser plants, grows and harvests his crops when and where he wants in his field.

Johnny Fraser considers water management one of the keys to profitably growing crops on his diversified New Zealand farm. Thanks to Precision VRI, a new precision irrigation product from Lindsay, Fraser plants, grows and harvests his crops when and where he wants in his field.

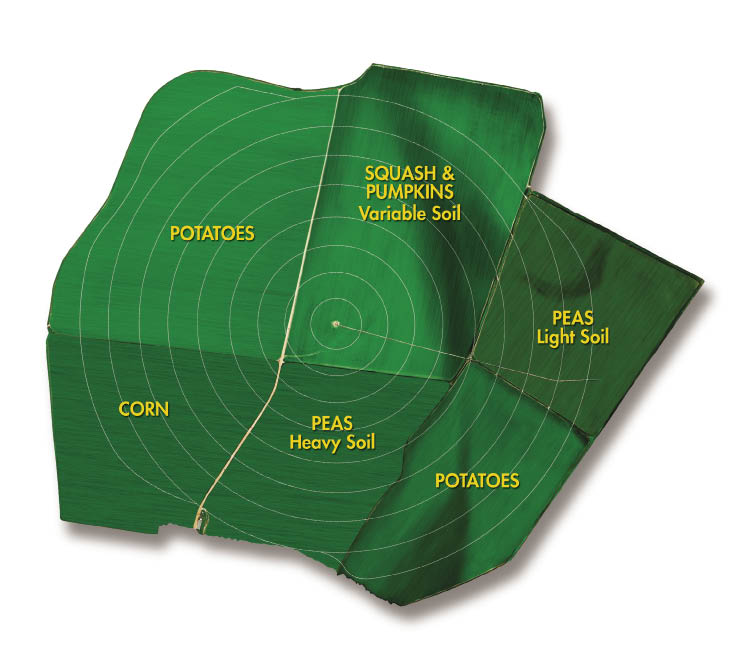

With easy-to-use mapping software, Precision VRI (variable rate irrigation) allows growers like Fraser to create custom irrigation zones that can be defined by soil type, topography, crop type or field obstacles. The variable rate program is then loaded into the Precision VRI controller that directs individual sprinklers through wireless nodes.

Fraser makes maximum use of Precision VRI to raise irrigated potatoes, peas, sweet corn, silage corn, wheat and barley-all in the same field. His Zimmatic MAXfield Custom corner system includes eight towers plus the corner arm, and irrigates the 227-acre (92-ha) field, which is split into five square blocks for a multitude of crops.

"Basically, I am using a circle to water square blocks, and that's where Precision VRI comes into play. I now have the flexibility to do whatever I like under that pivot as far as changing crops. I can adjust any time to suit my cropping needs," Fraser says.

Fraser's farm is located near Otane, on New Zealand's north island. Fraser says the climate in his area is similar to California's, so he is able to raise multiple crops throughout the year. Many of his crops, including the peas, potatoes and sweet corn, are processed for food.

"We have heavy soils, so managing the water is critical," he says. "It's important not to overwater and saturate the soil. The lighter soil areas require more water. Precision VRI works perfectly for my growing operation." Fraser's cropping patterns vary, but he describes a typical scenario in which his pea crop is followed by sweet corn and his potato crop is followed by wheat or a different crop. All of the crops are planted and harvested at different times of the year.

With Precision VRI, he is able to turn off the irrigation water over his pea crop, for example, to harvest the peas, while still irrigating his potato crop-all with the same pivot and in the same field.

Fraser estimates Precision VRI has resulted in one-third less water usage. "It's basically saving me 30 percent on costs since I don't have to pump as much water."

Fraser estimates Precision VRI has resulted in one-third less water usage. "It's basically saving me 30 percent on costs since I don't have to pump as much water."

While groundwater, the source for his irrigation, is still plentiful in his area, Fraser predicts managing and using water wisely will become more and more critical in the future.

"As a grower, I believe the single biggest thing you can do to increase yield is to manage your water, just like you manage your fertilizer, chemical and other crop inputs," Fraser says. "Potatoes are a great way to measure how well you are managing your water since they are very sensitive to over-or under-watering."

Fraser uses moisture probes in his field and reads the data manually because he wants to "get in the fields" and see for himself how the crops are doing.

He currently does not chemigate or fertigate but is considering it since Precision VRI gives him the flexibility to do so in the future. Fraser's 9500CC Custom Corner pivot was equipped with the Precision VRI system when he bought the pivot new.

"It's very simple to run. With Precision VRI, I have unlimited crop and agronomic options. I can plant and harvest when and where I want."